Hey there, my friends! Today, let me take you on a journey through the world of airbrushing and air compressors.

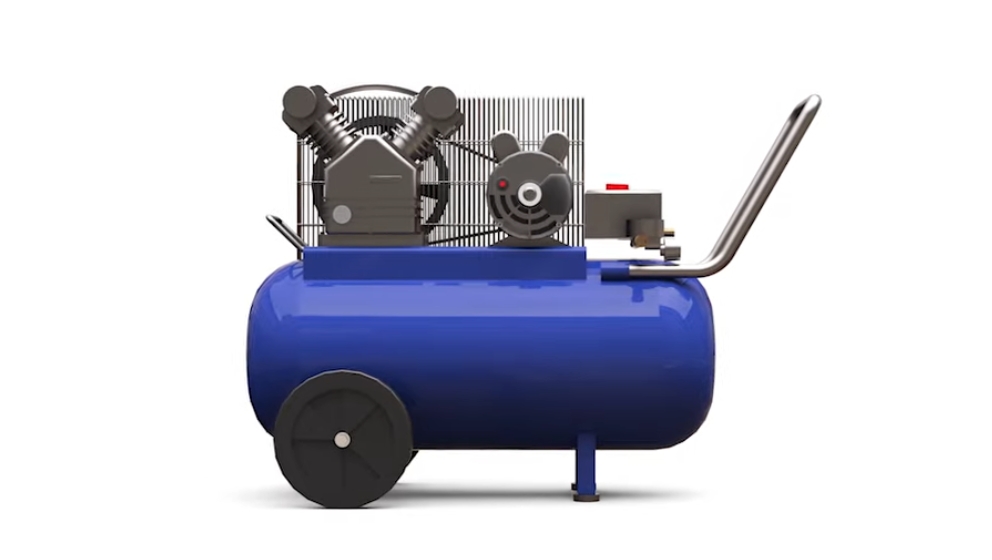

You see, airbrush compressors are these super cool devices that take in air at regular pressure and pump it out at a much higher one. This pressurized air is then sent through an airbrush, which allows you to apply paint or other media to a surface with ease.

I remember when I first started using an airbrush compressor, I was a bit intimidated by all the different shapes and sizes. But, let me tell you, once you get the hang of it, it’s a breeze! And trust me, there’s nothing quite like the feeling of creating a masterpiece with just a squeeze of the trigger.

Now, you might be wondering, why do we need air compressors in the first place? Well, let me tell you, they’re not just for artists! Compressed air is used in a variety of industrial processes, from powering pneumatic tools to transmitting energy in compact air motors. And if you’ve ever had to blow the dust off something or dry wet paint, you can thank compressed air for that too!

But, let’s not forget the real MVP of air compressors – their portability and versatility. These bad boys are a staple on construction sites and for good reason. I mean, who wouldn’t want a tool that can handle multiple tasks with ease?

And, just for the fun of it, I’ll add in a personal anecdote. I once had an air compressor that was so loud, it scared the cat out of the room every time I turned it on. But, let’s just say, the end result was totally worth it.

Common Terms and Definitions

Air Compressor

Air compressor, which takes in air at atmospheric pressure and delivers it at a higher pressure, is an essential component of many industrial processes.

Compressed air can be used to power pneumatic tools, transmit energy in compact air motors, or as a forced convection heating source. In addition, compressed air is often employed for tasks such as blowing the dust off surfaces and drying wet paint by blowing warm moist (but not wet) air over the surface. Air compressors are widely used in construction sites due to their portability and versatility.

You might also like our article best airbrush compressor.

Reciprocating Air Compressors

A reciprocating air compressor is a type of compressor that has pistons that move back and forth in cylinders. They are most often used in industrial settings, where they can be found on large trucks or trailers that transport compressed air to other sites.

There, they provide the power needed to run various types of heavy machinery such as drills and pneumatic hammers. Air compressors also exist at home; many people have them installed as part of their central heating systems. This user doesn’t require much energy and provides additional comfort during cold weather.

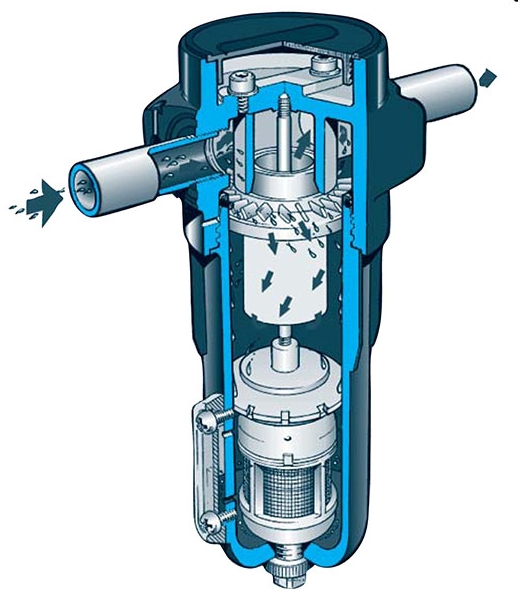

Moisture Separators

Moisture separators are devices that collect and remove moisture from the air. This is an essential step in the airbrush compressor process, as it helps keep the compressor running smoothly and prevents any damage that may be caused by excess moisture.

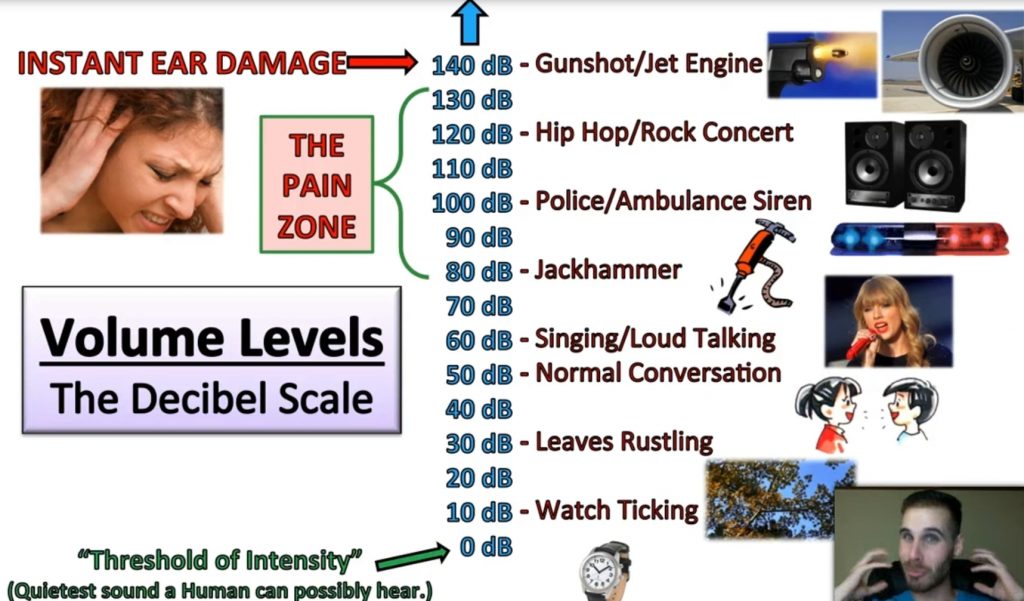

DB

The decibel (dB) is a term used to describe the relative loudness. This can be useful when comparing the noise levels of different appliances, such as heat pumps and air conditioners. Typically, these appliances will have a dB rating that falls somewhere between a human voice (70db) and a blender (88db).

Decibels measure how much energy passes through 1 square meter per second expressed in watts. The decibel scale is logarithmic, meaning that every 3 dB increase represents an increase in power by ten times. For example, for paper shredders: 60dB = 100W; 65dB = 1000W; 70dB = 10000W.

Displacement

The displacement of an airbrush compressor is an essential factor to consider when purchasing one. This is the air volume displaced by a complete stroke of the first-stage piston. It is measured in cubic feet per minute (CFM). This number can determine the size of the compressor you need for your project.

Filtration

Filtration is a process that removes solid particles and liquid droplets from the air. This is an essential step in air purification, as it helps improve the quality of the air. Filtration can be done through various methods, including mechanical filtration, activated carbon filtration, and ultraviolet germicidal irradiation.

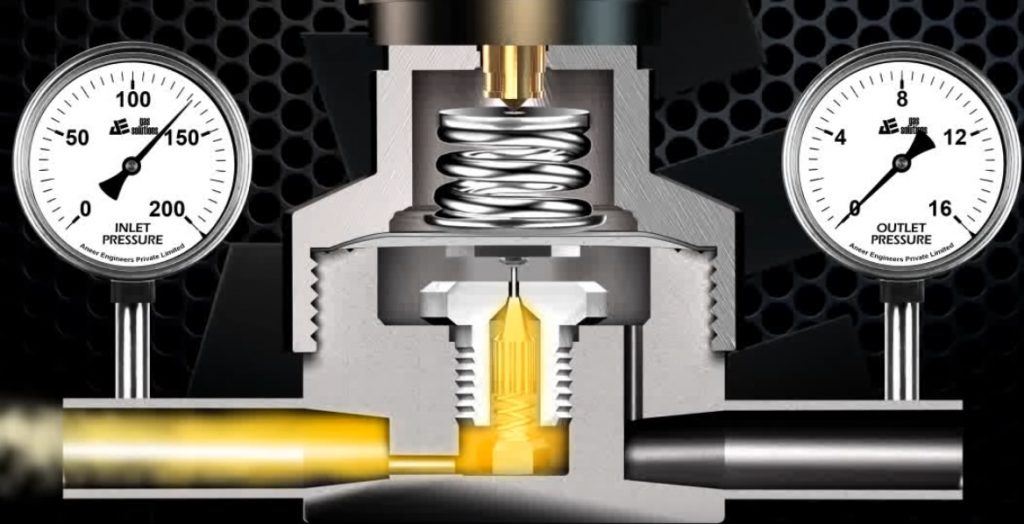

Air Pressure Regulator

The pressure regulator is a part of the air compressor that allows the user to adjust how much pressure is in the airline. This is important because it will enable the user to set the pressure to a comfortable level for them.

Maximum Pressure Ratio

The maximum pressure ratio is the highest-pressure level recommended for a compressor. If you exceed this level, you may damage the compressor and void your warranty.

Diaphragm Compressors

Diaphragm compressors work using a diaphragm that moves back and forth in a closed chamber. This happens because of the connecting rod’s motion under the diaphragm. The result is similar to what you would get with a reciprocating piston compressor.

CFM Cubic feet per minute

CFM Cubic feet per minute is the amount of air that a compressor can move in one minute. This is a significant rating to consider when purchasing a compressor, as it will determine how much air the compressor can move at a given pressure. Some dealers may advertise CFM displacement, which is always higher than CFM delivered. Another critical factor to consider when comparing compressors is the pressure given. A CFM rating at 40 PSI will always be a higher value than at 100 PSI or 175 PSI. It is more important to look at Delivered CFM at the same Pressures when comparing performance.

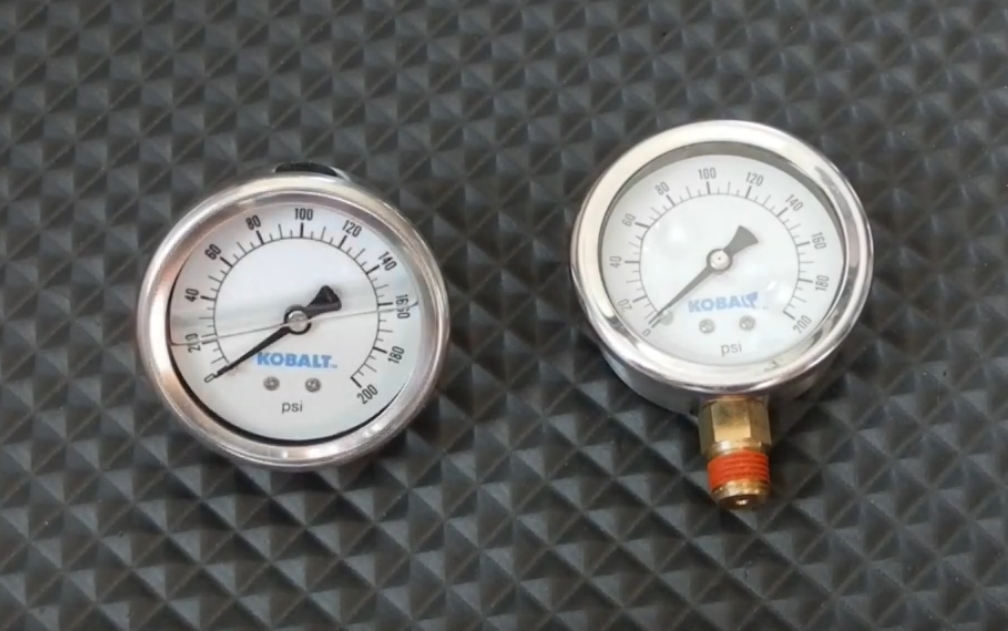

Gauges

Airbrush compressors use pressure gauges to monitor the tank’s pressure and the regulator. This allows you to keep track of how much air is available and ensures that the compressor is not over-pressurized.

Horse Power

Horse Power is a term used to describe the power of an electrical motor. Unfortunately, this term is vague, as it can be misleading because not all engines have the same Horse Power rating. When choosing a compressor, you should look for CFM delivered at a specific pressure and not rely on Horse Power alone.

Oil-less compressor

An oil more small compressor is a compressor that is not lubricated by oil. This type of compressor typically has a longer life span than traditional compressors and is more environmentally friendly because it does not produce emissions from the use of oil.

Pressure Switches

An electrical device is used to monitor and control the tank storage pressure. The Pressure Switch will automatically shut off the motor by opening a control circuit. The Pressure Switch may be wired directly to the engine in smaller units. However, the pressure switch is wired to a control circuit in larger units.

PSI

PSI is short for pounds per square inch and is a unit of pressure. It describes the storage pressure, operating stress, regulated anxiety, and air tool pressure requirement. When comparing strains and CFMs between teams, use CFM and PSI at the same values.

Regulator

The regulator is an inline device designed to reduce downstream air pressure to a specific adjustable setting. This device is essential in ensuring that the airbrush receives the appropriate level of air pressure to function correctly. Without a regulator, the airbrush would not be able to produce the desired level of spray.

FAQs

What is an airbrush compressor?

An airbrush compressor is a device that uses compressed air to power an airbrush. Airbrush compressors come in a variety of shapes and sizes, from small, portable units to larger, more powerful models. Depending on the specific model, an airbrush compressor may be used to power one or more airbrushes. Some compressors also have features like adjustable pressure settings and automatic shut-off.

What should I look for in an airbrush compressor?

There are a few things you should consider when purchasing an airbrush compressor:

- Airflow – You’ll want to make sure the compressor can provide enough airflow to support the airbrush. Most airbrushes will require at least 0.5 liters per minute (LPM).

- Ports – The ports on the compressor allow you to connect multiple airbrushes or other air tools. Make sure the compressor has enough ports for all of the devices you plan on using.

- Pressure Adjustment – Many compressors will have a pressure adjustment knob or switch. This is important because it allows you to control the amount of airflow and pressure that is sent to the airbrush.

- Tank Capacity – If you plan on using the compressor for extended periods of time, you’ll want to make sure it has a large enough tank to store compressed air. A larger tank will allow the compressor to run for longer without needing to stop and recharge.

- Noise – Some compressors can be quite loud. If you plan on using the compressor in a shared space, you’ll want to make sure it operates at a reasonable noise level.

How many PSI is an airbrush compressor?

An airbrush compressor typically produces around 15 to 30 PSI, though some models may produce up to 60 PSI. The specific pressure output will vary depending on the model and brand of compressor.

How much CFM do I need for airbrushing?

There is no one definitive answer to this question. The amount of CFM you need for airbrushing will depend on the size and power of the airbrush, as well as the thickness and texture of the paint you are using. A good rule of thumb is to start with around 60 CFM and then adjust as needed.

Hey there! I’m Richard Baker, a miniature painter who’s been in the game for a solid decade now. I’ve been painting miniatures for ten years and I’ve got a ton of tips and tricks to share with you all. My website is a treasure trove of knowledge that I’ve gathered from both my own personal experiences and from reading all sorts of books.

Leave a Reply